Double-Sided Carpet Tile Tape for Airplane Build Projects and Repairs

In the aviation industry, precision, durability, and reliability are critical factors in every aspect of construction and maintenance. While traditional adhesives, fasteners, and mechanical bonds remain the primary methods of assembly, alternative solutions such as double-sided carpet tile tape are gaining traction for specific applications in airplane repairs and building projects. This high-strength adhesive tape offers a combination of convenience, efficiency, and reliability that can be advantageous in certain aviation-related scenarios.

Understanding Double-Sided Carpet Tile Tape

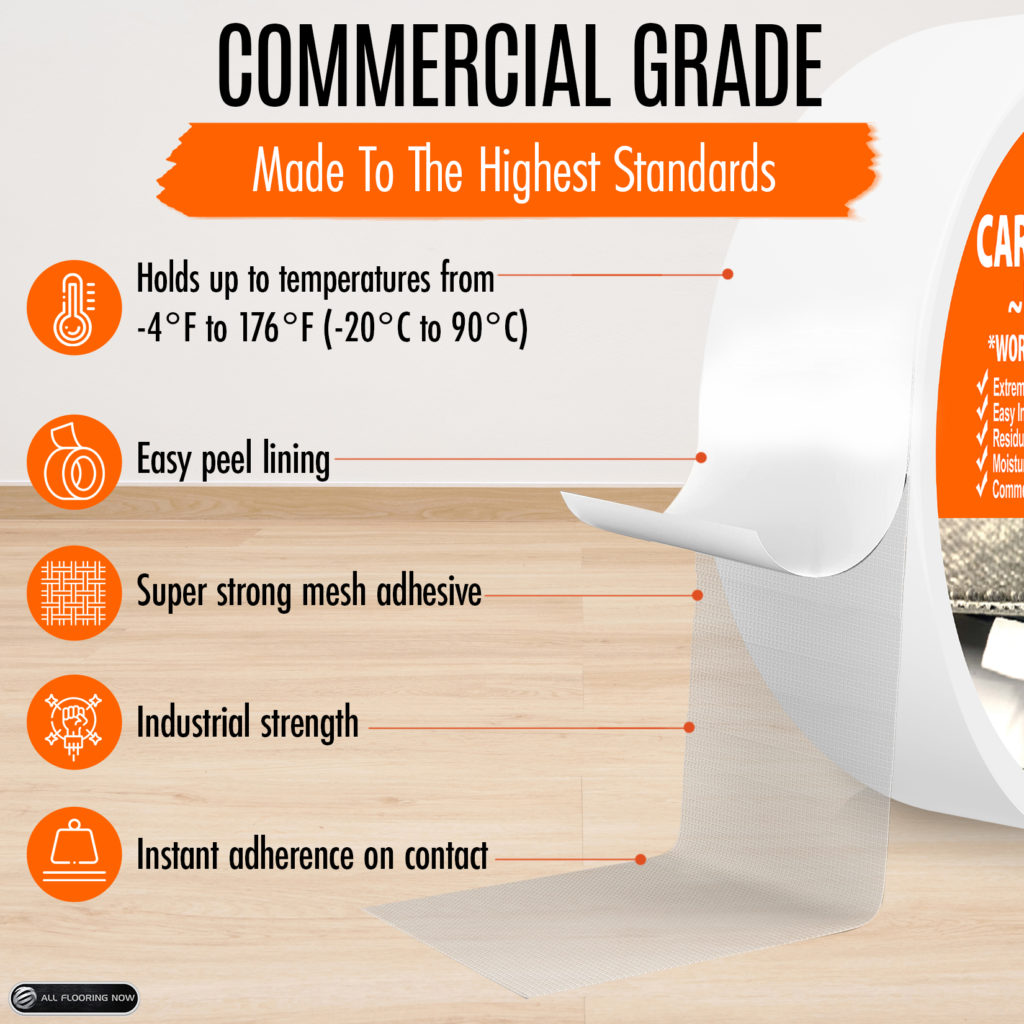

Double-sided carpet tile tape is a specialized adhesive product designed to provide strong, lasting adhesion between two surfaces. Traditionally used to secure carpets to floors without causing damage, this tape has evolved into a versatile tool that finds application in various industries, including aviation. It is composed of a durable carrier material, such as cloth or film, coated with pressure-sensitive adhesive on both sides. This structure enables it to create a firm bond while remaining flexible and easy to work with.

Applications in Airplane Repairs

1. Temporary Securing of Components

Aircraft maintenance often requires temporary positioning of materials before a permanent solution is applied. Double-sided carpet tape can hold lightweight panels, insulation materials, or wiring in place while more permanent fasteners or adhesives are prepared and applied.

2. Interior Fixes and Enhancements

Aircraft interiors require constant upkeep to maintain passenger comfort and safety. Carpet tape is frequently used to secure floor coverings, soundproofing materials, and decorative panels without requiring extensive mechanical alterations. It ensures a strong hold while allowing for easy removal and replacement during routine maintenance.

3. Emergency Repairs

In urgent situations, such as securing loose insulation, temporarily attaching lightweight components, or reinforcing protective covers, double-sided carpet tape can serve as a quick and effective temporary repair solution until a more robust fix is implemented.

Applications in Airplane Building Projects

1. Composite Material Bonding

Modern aircraft construction relies heavily on composite materials for improved performance and weight reduction. Double-sided carpet tile tape can be utilized in initial positioning of these materials before they are permanently bonded using epoxy resins or mechanical fasteners.

2. Aerodynamic Modifications and Prototyping

During the research and development phase of aircraft design, engineers frequently create prototype modifications to test aerodynamics and structural integrity. Carpet tape allows for quick attachment of fairings, aerodynamic panels, and other elements during testing without compromising the integrity of the aircraft's structure.

3. Electrical Wiring and Insulation

Properly securing wiring and insulation is crucial for both safety and functionality in an aircraft. Carpet tape provides a reliable solution for holding insulation in place, bundling wires, and preventing unnecessary vibrations that could lead to damage over time.

Advantages of Using Double-Sided Carpet Tile Tape in Aviation

-

Ease of Application: Unlike traditional adhesives or mechanical fasteners, double-sided tape can be applied quickly without the need for specialized tools or training.

-

Lightweight: Every ounce matters in aviation, and carpet tape offers a lightweight bonding solution compared to screws, rivets, or heavier adhesives.

-

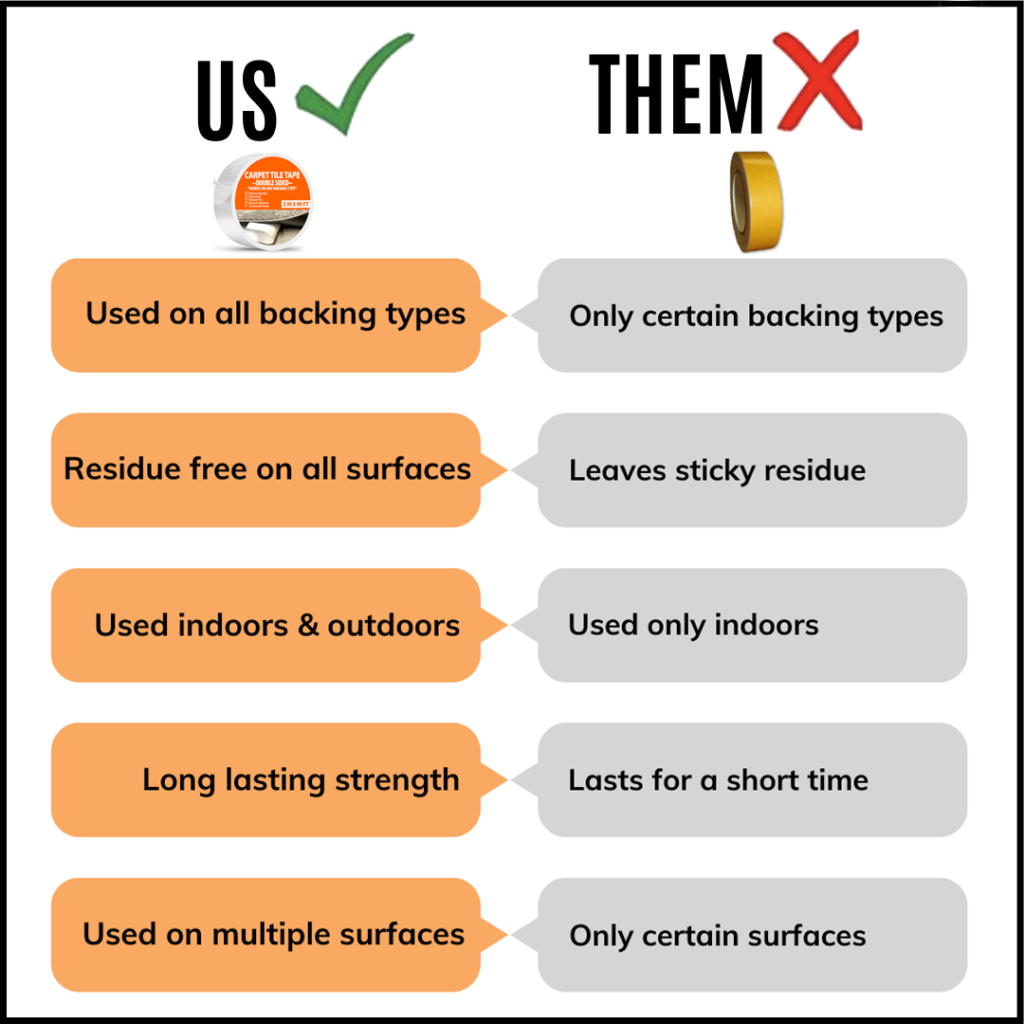

Non-Damaging Removal: When used for temporary applications, high-quality carpet tape can be removed without leaving residue or causing damage to delicate surfaces.

-

Cost-Effective: In certain applications, using double-sided tape can reduce costs associated with complex repairs or installations.

- Vibration and Noise Reduction: The flexible nature of carpet tape helps absorb vibrations and reduce noise levels inside the aircraft cabin.

Considerations and Limitations

While double-sided carpet tile tape has its advantages, it is important to consider its limitations. Not all carpet tapes are designed for extreme temperatures, high humidity, or direct exposure to aviation fuels and oils. For critical structural applications, engineers must evaluate whether the adhesive strength and durability meet aviation standards.

Additionally, regulatory compliance must always be a top priority. Aviation authorities such as the Federal Aviation Administration (FAA) or the European Union Aviation Safety Agency (EASA) set strict guidelines for materials used in aircraft construction and maintenance. Before using double-sided carpet tape for any application beyond temporary fixes, it is crucial to verify that it aligns with industry standards and safety regulations.

Double-sided carpet tile tape offers a surprisingly versatile and effective solution for various applications in airplane repairs and building projects. Whether securing insulation, aiding in prototype development, or assisting with emergency fixes, this adhesive material provides significant advantages in efficiency, ease of use, and lightweight bonding. However, proper selection and regulatory compliance are essential to ensure safety and performance. As aviation technology continues to evolve, innovative uses of materials like double-sided carpet tape will likely play a role in improving maintenance processes and aircraft construction techniques.