Keeping It Together: The Science Behind Strong Double Sided Tape

Double-sided tape, a seemingly simple adhesive solution, plays a significant role in various applications, from household repairs to industrial assembly. Its ability to securely bond different surfaces with ease has made it an indispensable tool for countless projects. Behind the scenes, there is an intricate science that governs the adhesive strength of double-sided tape. In this article, we will explore the technology and engineering principles that make double-sided tape so effective in bonding different surfaces.

Understanding Adhesion

Before delving into the specifics of double-sided tape, it's crucial to understand the concept of adhesion. Adhesion refers to the attractive forces that exist between the adhesive and the substrate (the surface to which the adhesive is applied). These forces enable the adhesive to cling to the substrate and create a strong bond.

- Key Components of Double-Sided Tape

Double-sided tape typically consists of three main components:

Carrier Material

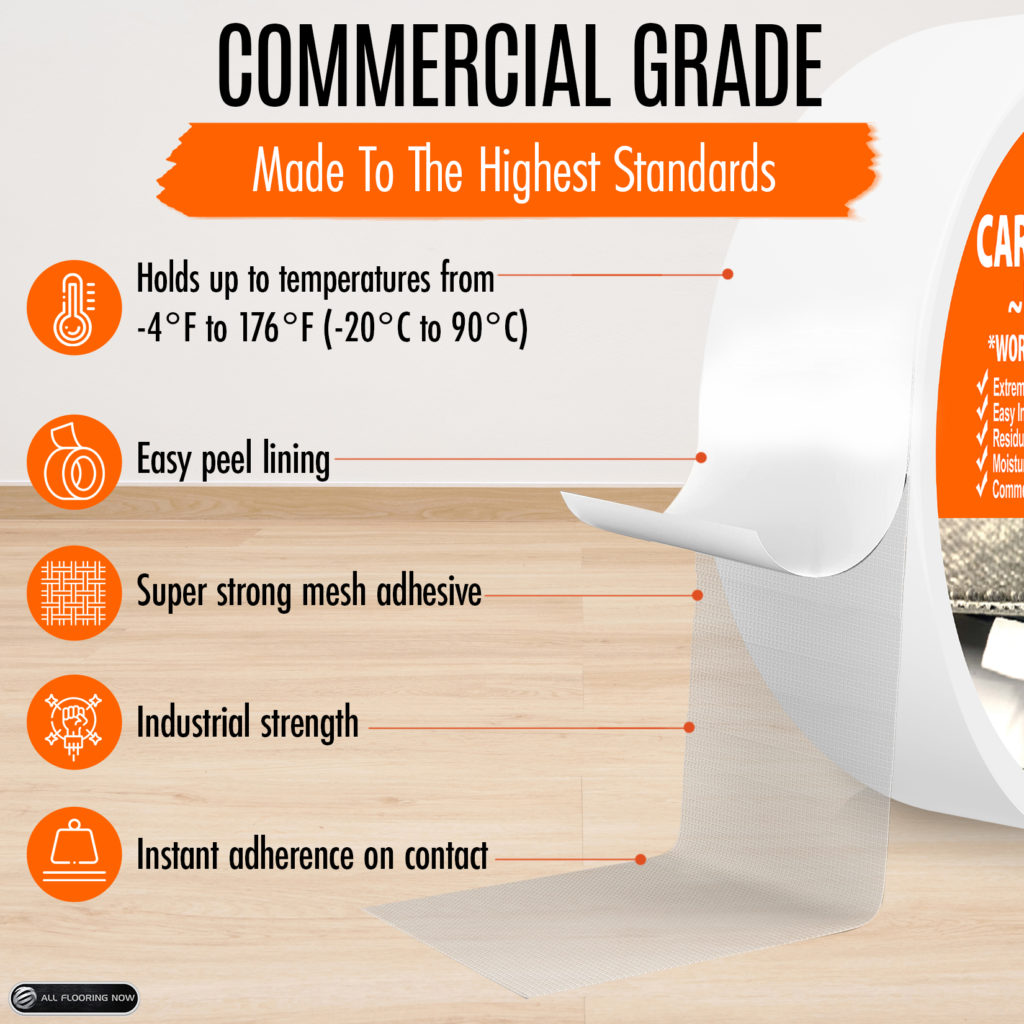

The carrier material serves as the backbone of the tape, providing strength and stability. It can be made from various materials, such as foam, film, or paper. The choice of carrier material depends on the intended application and the properties required for bonding.

Adhesive Layer

The adhesive layer is the heart of the double-sided tape. It is responsible for creating the bond between the tape and the two surfaces it is sticking together. Different types of adhesives are used in double-sided tape, including acrylics, rubbers, and modified silicones, each with its unique properties.

Release Liner

The release liner is a protective layer on the adhesive side of the tape. It is designed to be easily removed before application, exposing the adhesive for bonding. The release liner ensures that the adhesive does not stick to unwanted surfaces before use.

- Mechanisms of Adhesion in Double-Sided Tape

The adhesive strength of double-sided tape relies on various mechanisms of adhesion. These mechanisms include:

Mechanical Adhesion

The adhesive material penetrates the microscopic imperfections on the surface of the substrate. This creates a mechanical bond, much like the interlocking of puzzle pieces, enhancing the tape's grip.

Van der Waals Forces

Van der Waals forces are weak intermolecular forces that exist between all molecules. In the context of double-sided tape, these forces come into play when the adhesive molecules come close to the substrate molecules, allowing the adhesive to create a molecular bond.

Diffusion

In some cases, the adhesive molecules can diffuse into the substrate's surface, forming a bond at a molecular level. This diffusion enhances the strength of the adhesive bond.

Wetting

Wetting refers to the adhesive's ability to spread over the substrate's surface, maximizing contact between the adhesive and the substrate. Better wetting leads to improved adhesion.

- Tailoring Adhesive Formulations for Specific Applications

Different applications demand different adhesive properties. For example, bonding lightweight materials like paper or fabric requires a different adhesive formulation compared to bonding heavy metals or plastics. Manufacturers tailor the adhesive formulations to suit specific applications by adjusting factors such as:

Cohesion and Tack

Cohesion refers to the internal strength of the adhesive itself, while tack refers to its ability to adhere quickly to a surface. Striking the right balance between cohesion and tack ensures that the tape bonds effectively and stays bonded over time.

Shear and Peel Strength

Shear strength measures the adhesive's ability to resist sliding forces, while peel strength measures its resistance to being pulled away from the surface. The choice between these two properties depends on the intended application.

Temperature and Environmental Resistance

Some applications may expose the tape to extreme temperatures, moisture, or chemicals. Adhesive formulations can be engineered to withstand such harsh environments.

- Enhancing Adhesion with Surface Preparation

While double-sided tape can offer strong adhesion on various surfaces, proper surface preparation can further enhance its performance. Cleaning the surfaces to remove dirt, oil, or other contaminants ensures a clean bonding surface. Additionally, some adhesives work better on rough or porous surfaces, while others excel on smooth or non-porous substrates.

- Backing Materials for Specific Applications

The choice of carrier material (foam, film, or paper) also impacts the tape's adhesive strength. For instance, foam-backed double-sided tape offers excellent cushioning properties and is ideal for mounting objects on uneven surfaces or providing vibration dampening. Film or paper-backed tapes, on the other hand, are more suitable for smooth and flat surfaces.

- Longevity and Aging

Double-sided tapes are engineered to provide long-term adhesion, maintaining their bond strength over time. Aging and exposure to external factors can affect the adhesive properties, but high-quality tapes are designed to withstand these challenges and retain their performance.

Double-sided tape's adhesive strength is the result of a sophisticated combination of science, engineering, and material design. Understanding the mechanisms of adhesion and the role of carrier materials, adhesives, and release liners helps us appreciate the versatility and effectiveness of double-sided tape in bonding different surfaces.

From creating reliable bonds between lightweight materials in DIY projects to securing heavy components in industrial applications, double-sided tape is a testament to how scientific principles can be harnessed to make our lives more convenient and efficient. As technology continues to advance, we can expect even more innovative developments in double-sided tape, providing solutions for a wide range of bonding challenges in the years to come.