The Importance of High Quality Double Sided Tape in Industrial Applications

In the fast-paced world of industrial applications, efficiency, reliability, and safety are paramount. From heavy machinery assembly to securing critical components in extreme conditions, the adhesive solutions employed in these environments play a pivotal role in ensuring seamless operations. Among these solutions, high-quality double-sided tape emerges as a game-changer. In this article, we will explore the significance of using reliable and robust double-sided tape in industrial settings, where bonding and durability are critical factors.

- The Versatility of Double-Sided Tape

Double-sided tape is a unique adhesive product designed to adhere to two surfaces simultaneously, offering a reliable and invisible bonding method. One of the key reasons for its popularity in industrial applications is its versatility. From mounting lightweight components to securing heavy machinery parts, double-sided tape provides a cost-effective and efficient solution for a wide range of bonding needs.

- Enhanced Efficiency in Assembly

In the fast-paced world of industrial manufacturing, time is of the essence. High-quality double-sided tape allows for quicker assembly processes compared to traditional bonding methods like screws, rivets, or liquid adhesives. The ease of application and immediate bonding capabilities of double-sided tape significantly reduce production time and costs, leading to enhanced overall efficiency.

- Bonding Dissimilar Materials

Industrial applications often involve the need to bond dissimilar materials, such as metal to plastic or rubber to glass. Double-sided tape with specific formulations can create a strong and reliable bond between such materials, overcoming the challenges associated with traditional adhesives that might struggle with incompatible substrates.

- Vibration Dampening and Impact Resistance

In industrial settings, heavy machinery and equipment are subject to constant vibrations and impacts. High-quality double-sided tapes with superior bonding properties can act as vibration dampeners, reducing wear and tear on components and minimizing the risk of mechanical failures.

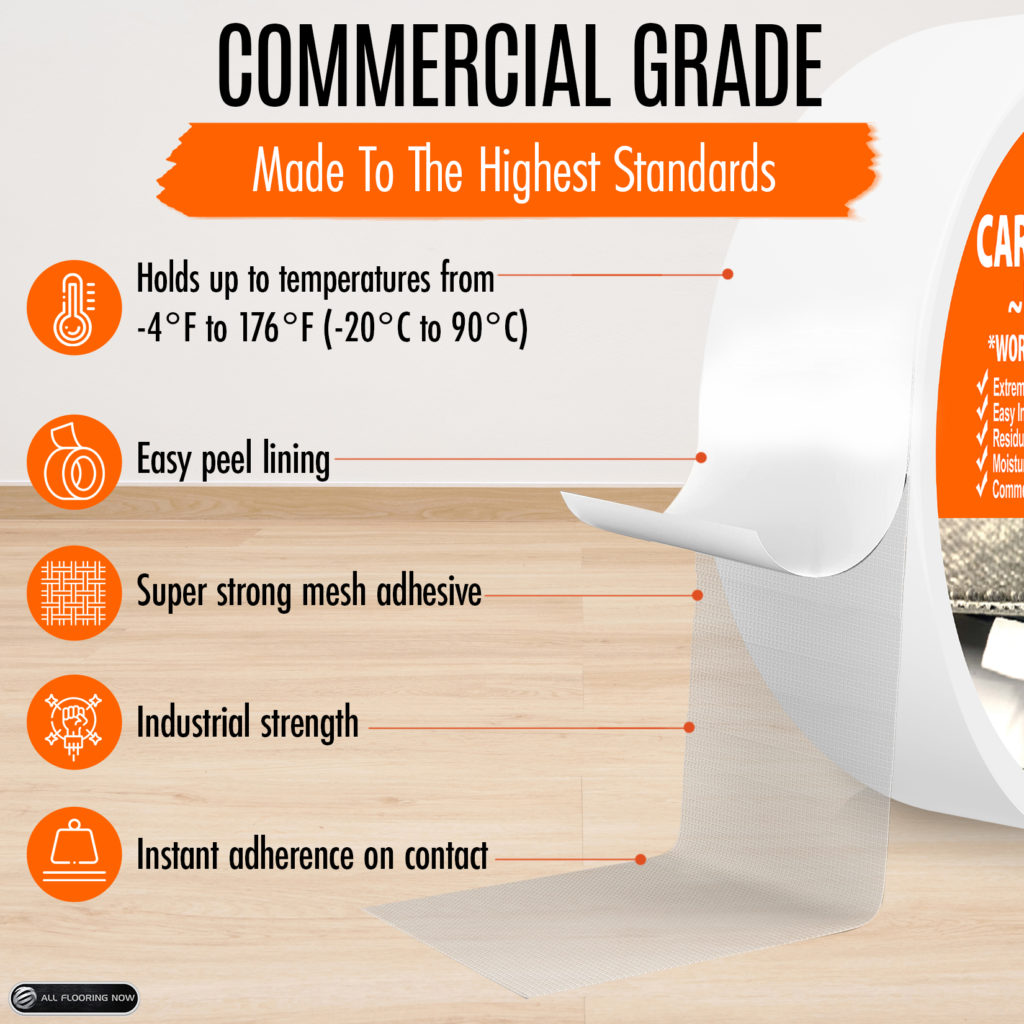

- Temperature and Weather Resistance

Industrial environments can expose adhesives to extreme temperature fluctuations and harsh weather conditions. Cheap and low-quality tapes may fail to maintain their adhesive strength under such conditions, leading to operational disruptions and safety hazards. On the other hand, high-quality double-sided tape formulated to withstand a wide range of temperatures and weather conditions ensures consistent performance, making it a reliable choice for various applications.

- Reducing the Need for Mechanical Fasteners

Mechanical fasteners like nuts, bolts, and screws have long been the go-to choice for industrial bonding. However, these fasteners can add weight, weaken materials, and create potential weak points in the structure. Double-sided tape, when chosen wisely, can replace or complement mechanical fasteners, reducing weight, enhancing structural integrity, and streamlining the overall design.

- Clean and Aesthetically Pleasing Bonding

Industrial applications often demand a clean and aesthetically pleasing finish. Double-sided tapes offer a seamless and invisible bonding method, eliminating the need for unsightly screws or rivets that may affect the product's visual appeal. This is especially important in consumer-facing industries where product aesthetics influence customer perception.

- Flexibility and Adaptability

The adaptability of high-quality double-sided tape extends beyond bonding diverse materials. Some tapes are designed to be repositionable, allowing for adjustments during the assembly process. This flexibility not only saves time but also minimizes material wastage.

- Ensuring Workplace Safety

Industrial settings are inherently risky, and ensuring workplace safety is a top priority. High-quality double-sided tape plays a significant role in securing components and preventing potential hazards caused by loose or dislodged parts. Additionally, by eliminating the need for protruding fasteners, it reduces the risk of injuries to workers.

- Long-Term Durability and Reliability

In industrial applications, longevity and reliability are non-negotiable. High-quality double-sided tapes are engineered to withstand the test of time, ensuring that bonded components remain securely in place throughout their operational life. This not only reduces maintenance costs but also prevents downtime due to adhesive failures.

The importance of using high-quality double-sided tape in industrial applications cannot be overstated. Its versatility, efficiency, and ability to bond dissimilar materials make it an indispensable asset in various industries. The advantages of vibration dampening, impact resistance, and temperature tolerance contribute to the durability and reliability of components, enhancing overall safety in the workplace. Additionally, its ability to provide a clean and aesthetically pleasing finish, along with the ease of application, streamlines assembly processes and reduces production time and costs. Embracing the power of reliable heavy duty double-sided tape can elevate industrial operations to new heights of efficiency and performance.